Whey Process Expansion

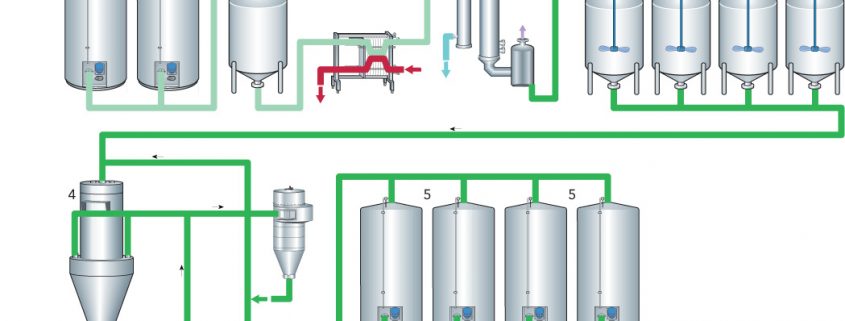

An existing dairy processing plant in the Midwest contracted CEI™ to provide the preliminary and final process engineering design to expand the capacity of the existing dairy production facility by several million pounds of milk per day for expanding their Whey production capabilities. The total project budget was approx. $155MM and the duration was approx. 2 years. The process design work provided by CEITM incorporated both existing (to be modified) and new processes requiring P&ID development and equipment layout drawings. CEI™ assisted with equipment and installation services procurement by providing detailed drawings, design criteria and specifications for new silos, tanks, heat exchangers and sanitary valve manifolds. To coordinate the process design with the controls group, CEITM formulated PIN charts and provided functional requirements for process control.

CEI’s scope of work included the following existing processes to be modified or newly designed systems:

- Receiving & Load-Out

- Product Storage (Raw Milk, Skim, Cream, Whey, Waste)

- HTST Pasteurizers & Separation

- Membrane Systems

- Crystallization

- CIP Systems

- Water Systems (Hot Water Skids, Process Water, UV Systems)

- Piping and Valve Manifold Designs

During the preliminary engineering phase of the project, CEI™ was tasked with providing a viable project cost estimate for the processes listed above that allowed the client to submit the project for formal corporate approval. Upon approval of the process design, the final design engineering, completed by CEI™, required refining the overall process requirements while integrating client requests including coordination with architect, structural/utility engineering and process equipment suppliers.